Sand Blast Etching

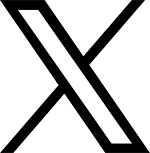

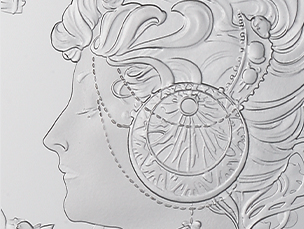

A three-dimensional world spread out in the glass

“Sandblast etching” involves blowing fine sand onto the surface of the glass and engraving patterns by hand work. Three-dimensional formative beauty is created in thin glass with a thickness of about 5 mm to 12 mm. The depth is created by the slight difference in carving depth of 0.1 mm. Even in Iriya, where the glass industry is thriving, only a very limited number of skilled craftsmen are able to handle this delicate technique that transforms transparent glass into art. A beautiful three-dimensional world confined in transparent glass, neither in color nor in black and white. The delicate formative beauty that captures the eyes and hearts of those who see it is loved not only as interior glass that colors spaces, but also as memorial art that engraves important memories and remembrances without fading.

IRIYA’s skills

which are kept improving by artisans

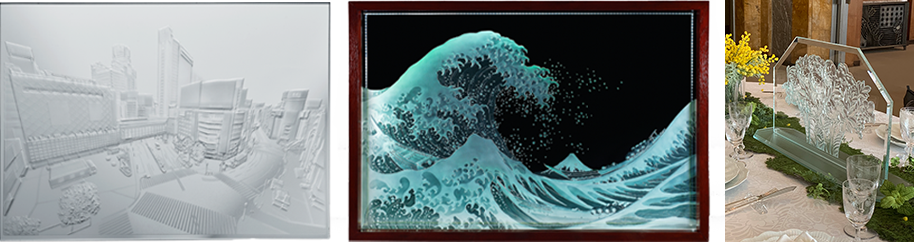

Draw a design suitable for etching

Sandblast etching begins with creating a rough sketch of the design. We imagine three-dimensional structures such as photographs and paintings that will be the motif in our head, and we try and error how to express it in the glass. Even if the motif is flat, we draw a design while imagining it in three-dimensional. Sometimes we look at the real article or look it up in books, expanding our image and pursuing a more delicate three-dimensional expression. We propose designs with various ideas.

Drawing the design by computer

The digitized design

A 0.1mm depth world expressed with

sand on a canvas of glass

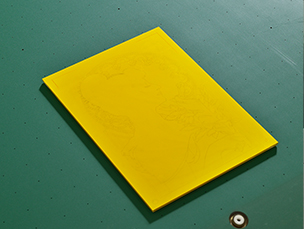

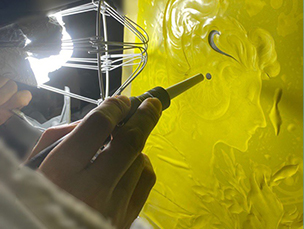

Sand etching engraves by cutting and peeling the vinyl pasted on the entire glass along the design and blowing sand with compressed air by a compressor.

In general sand etching, the pattern is two-dimensional because it is completed in one carving, but at our company, by gradually finely repeating this process, we bring out a three-dimensional effect with an intonation that cannot be imitated by others.

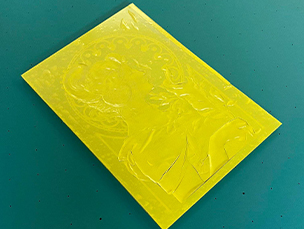

The thickness of the glass that becomes the canvas is about 5 mm to 12 mm. The finished figure looks like a three-dimensional object with a deep depth, as if it were fitted in a mold, but the carving depth is less than 1 cm, and it is a detailed work that is adjusted to “0.1 mm or less”. Since the carving is done from the other side of the glass, we carefully check how it looks from the front before proceeding. Once carved, it can never be restored.

Therefore, it is extremely important to be able to imagine how to engrave the design along with the finished figure. It is a skill and technique that cannot be mastered without a lot of experience, and there are very few craftsmen who can handle sand etching with a three-dimensional effect. For example, it is not possible to engrave three-dimensionally unless an idea of the structure of each layer of petals is in detail. By constantly observing things and accumulating knowledge, we expand our image of three-dimensional structures and continue to refine our expressions in a more natural way.

1

Draw a design by a computer

2

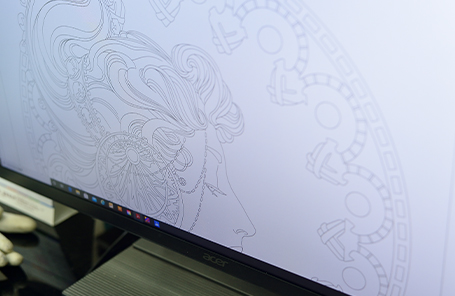

Digitized design original

3

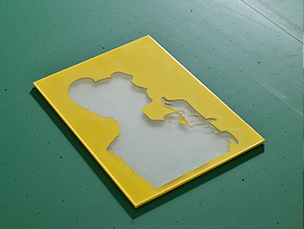

Cut the design on a flatbed plotter → Data output cut

4

Cut design to masking

5

Supplementary cutting and masking removal work for sandblasting work

6

Sandblasting work

7

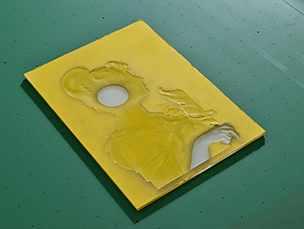

The masking has been removed to carve the overall three-dimensional effect (Relief)

8

Sandblasting while removing the masking

9

Masking the extruded part of some parts of the solid (Relief carving and Sequence Carving)

10

Chemicals are poured onto the carved glass surface to give it a luster

11

Apply tape again and cut the part to be shaded.

12

Lightly sand while peeling off the tape to shade.

13

Completed

Pursuing the possibilities of sand etching such as mirrors and 3D expressions

We continue to pursue various expressions using sandblast etching technology. Etching on mirrors is also possible. The etching mirror is different from the etching glass that is carved from the back side.

Taking advantage of the characteristics of the mirror, the surface is carved and finished. We also accept requests to express two-dimensional motifs such as illustrations and manga three-dimensionally with sand etching. Etching, which can be said to be between 2D and 3D, is recommended for those who are looking for a new expression way.

Examples of introduction to homes and shops